Grounding A Metal Building

As a property owner with a metal building, grounding it should be a top priority. Not only does proper grounding ensure safety, but it also protects electrical equipment from damage and dysfunction. In this article, we will explore the importance of grounding a metal building and provide tips for doing it right.

The Pain Points of Grounding a Metal Building

Ensuring that a metal building is properly grounded can be a challenging task. Many property owners are not aware of the importance of grounding or are not familiar with the best practices for doing it effectively. As a result, electrical equipment can suffer damage, and occupants can be at risk of electric shock.

The Target of Grounding a Metal Building

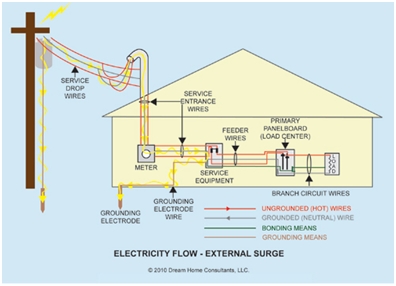

The primary goal of grounding a metal building is to provide a path for electrical current to travel safely to the earth. When electrical equipment malfunctions or is struck by lightning, the current will follow the path of least resistance. Proper grounding ensures that the current does not travel through equipment, structures, or individuals, reducing the risk of electric shock, fire, and damage to equipment.

Summary of Best Practices for Grounding a Metal Building

When grounding a metal building, the following best practices should be observed:

- Ensure that the grounding system is installed by a licensed electrician.

- Use copper grounding rods at least eight feet deep and eight feet apart for effective grounding.

- Connect all metal structures and equipment to the grounding system.

- Regularly test the grounding system for continuity and effectiveness.

Importance of Using a Professional for Grounding a Metal Building

While some property owners may attempt to install a grounding system on their own, it is highly recommended to use a licensed electrician for safety and effectiveness. A professional electrician can help property owners determine the best location for grounding and ensure that all equipment and structures are connected to the system. Additionally, professionals have the equipment and knowledge needed to test the grounding system for effectiveness, ensuring that it is in compliance with local codes and regulations.

Common Mistakes in Grounding a Metal Building

One of the most common mistakes in grounding a metal building is failing to connect all metal structures and equipment to the system. When equipment is not connected to the grounding system, there is a risk of electric shock and damage to the equipment. Additionally, some property owners may not use enough grounding rods or bury them deep enough, reducing the effectiveness of the grounding system.

Tips for Avoiding Common Mistakes in Grounding a Metal Building

To avoid common mistakes in grounding a metal building, ensure that all metal structures and equipment are connected to the grounding system. Additionally, use copper grounding rods at least eight feet deep and eight feet apart to ensure that the grounding system is effective. Finally, have the system tested regularly for continuity and effectiveness to catch any problems early and prevent damage to equipment or individuals.

Question and Answer about Grounding a Metal Building

Q: How frequently should I test my grounding system?

A: It is recommended to test your grounding system at least once a year for continuity and effectiveness, but more frequent testing may be necessary if there are significant changes to the building or equipment.

Q: Why is copper a better choice for grounding rods?

A: Copper is a better choice for grounding rods because it is highly conductive and resists corrosion, which ensures that the grounding system remains effective over time.

Q: Can I ground a metal building to a nearby water pipe?

A: No, grounding a metal building to a water pipe is not recommended because it can cause electrolysis, which can damage the pipe over time.

Q: Is it necessary to ground a metal building if there is no electrical equipment inside?

A: Yes, it is still necessary to ground a metal building even if there is no electrical equipment. Proper grounding ensures that occupants are safe from electric shock, and reduces the risk of fire and other damage to the building.

Conclusion for Grounding a Metal Building

Proper grounding is essential for any metal building, as it ensures the safety of occupants and protects electrical equipment from damage. To ensure that your grounding system is effective, use a licensed electrician, use copper grounding rods, connect all metal structures and equipment to the system, and test the system regularly for continuity and effectiveness. By following these best practices, you can ensure safe and reliable grounding for your metal building for years to come.

Gallery

Grounding And Bonding — Part 1 Of 2

Photo Credit by: bing.com / metal electrical water structure pipe building grounding conductor code bonding residential mike requirements graphics codes allows section interior pipes buildings

8 Tips To Avoid Ground Loops With Signal Level Circuits

Photo Credit by: bing.com / grounding steel building connection ground signal structural electrical metal bonding circuits loops avoid level tips data cables dealing when

Grounding System For A Metal Building — Northernarizona-windandsun

Photo Credit by: bing.com / grounding building metal system 7k

Electrical Grounding Best Practices

Photo Credit by: bing.com / grounding protects surges

Grounding Of Metal Buildings - E&S Grounding Ask The Experts

Photo Credit by: bing.com / grounding

0 Response to "Grounding A Metal Building"

Post a Comment