Feeder Tap

Feeder tap may seem like a complex topic, but understanding the rules and regulations that govern this practice is essential for both electricians and property owners. In this blog post, we will explore feeder tap in detail, answering common questions and providing insights into this critical aspect of electrical work. Read on to learn more!

Pain Points

Feeder tap can be a point of confusion for many electricians, particularly those who are not familiar with the National Electric Code (NEC). Violating feeder tap regulations can lead to hazardous conditions, putting both people and property at risk. Knowing the rules surrounding feeder tap is essential for staying compliant and keeping work sites safe.

Target of Feeder Tap

Feeder tap is a term that refers to a portion of an electrical installation that branches off from the main feeder circuit and serves a specific area, such as a single-phase or three-phase motor. The target of feeder tap is to provide a safe, reliable electrical connection between the feeder circuit and the devices it serves. This connection must adhere to strict rules and regulations, which are established in Section 240.21 of the NEC.

Main Points

Feeder tap is an important aspect of electrical work that can have serious implications if not handled properly. Essentially, feeder tap is a tap that goes off of the main feeder circuit to provide power to a specific location or device. The NEC has established strict rules regarding feeder tap, which vary depending on the length of the tap and the size of the wire being used. Generally, feeder tap cannot exceed 10 feet in length and must be composed of wire that is at least as large as the circuit it is tapping from.

Feeder Tap and the NEC

Section 240.21 of the NEC outlines regulations surrounding feeder tap, including requirements for the size of wire used and the length of the tap. Violating these regulations can have serious consequences, both for those working on the electrical installation and for the property owners who rely on it. As an electrician, I have encountered many situations where improper feeder tap was a major problem, causing power outages and other issues that could have been avoided with proper adherence to NEC regulations.

Feeder Tap Installation

One of the most critical aspects of feeder tap installation is selecting the correct size of wire. It is essential to use wire that is at least as large as the circuit it is tapping from to ensure safe, reliable power delivery. Additionally, the length of the tap cannot exceed 10 feet. When installing feeder tap, it is also essential to follow all NEC regulations, including proper grounding and bonding.

Feeder Tap Regulations

As previously mentioned, Section 240.21 of the NEC outlines regulations for feeder tap. These regulations include requirements for wire size, tap location, and length of the tap. Additionally, feeder tap must be installed in accordance with all other relevant NEC regulations, including bonding and grounding practices.

Feeder Tap Maintenance

Maintaining correct feeder tap operation is essential for reliability and safety. Perform regular inspection of tap connections and associated components, and address any necessary repairs or upgrades promptly. Proactively addressing issues related to feeder tap can help minimize downtime and keep electrical systems functioning optimally.

Question and Answer

What is a feeder tap?

A feeder tap is a portion of an electrical installation that branches off from the main feeder circuit and serves a specific area or device.

What are the NEC requirements for feeder tap?

The NEC establishes strict requirements for feeder tap, including rules surrounding wire size, tap location, and length of the tap.

What happens if feeder tap regulations are not followed?

Violating feeder tap regulations can have serious consequences, including safety hazards and unreliable power delivery. As such, it is essential to follow all relevant NEC regulations when working with feeder tap.

How often should feeder tap be inspected?

Feeder tap should be inspected on a regular basis to ensure proper operation and address any necessary repairs or upgrades. The frequency of these inspections may vary depending on the specifics of the installation.

Conclusion of Feeder Tap

Feeder tap is an important aspect of electrical work that requires careful attention to detail and adherence to strict rules and regulations. Violating these regulations can have serious consequences, so it is essential to work with an experienced electrician who understands how to properly install and maintain feeder tap. Remember to always follow NEC regulations when working with feeder tap to ensure a safe, reliable electrical installation.

Gallery

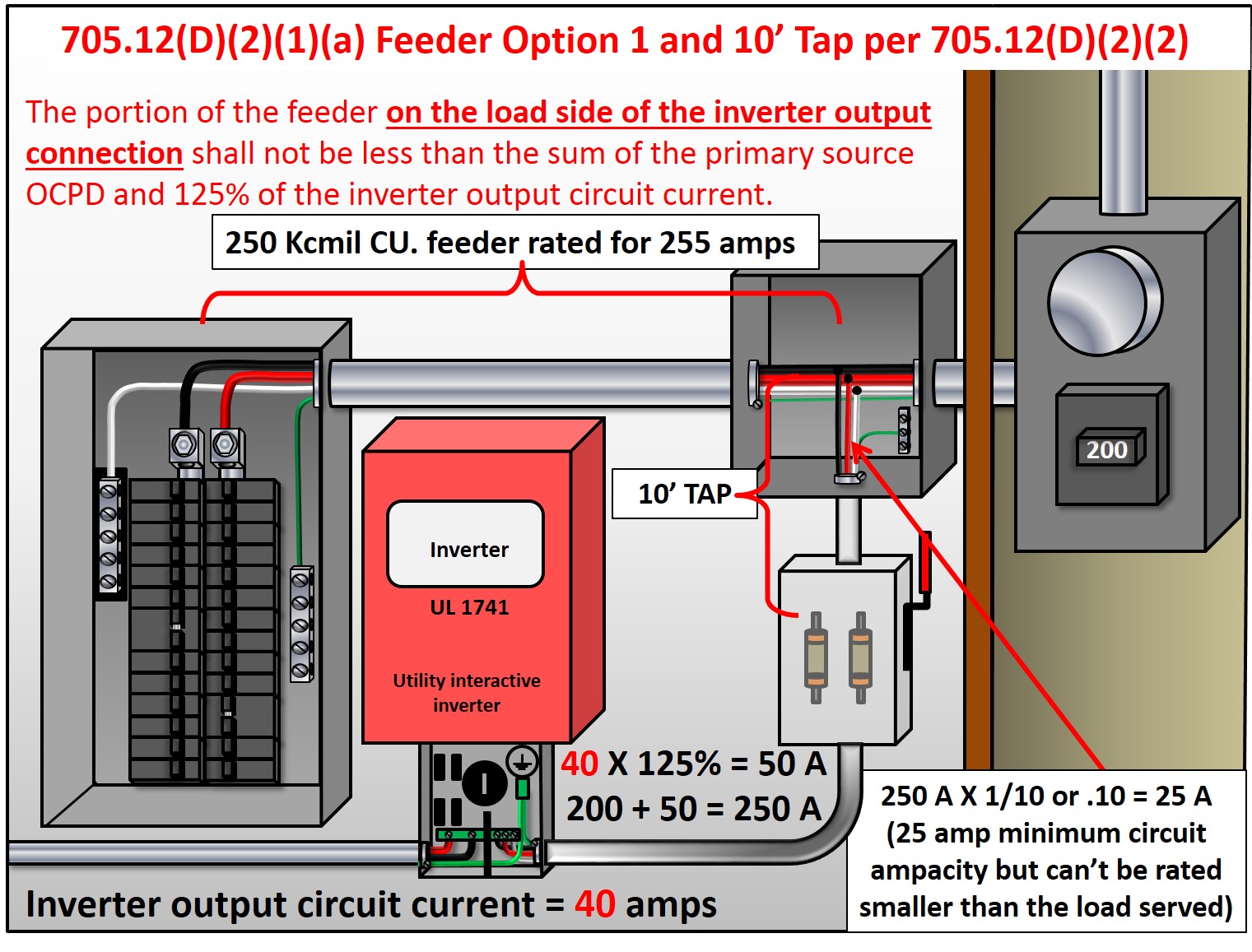

240.21(B) Feeder Taps.

Photo Credit by: bing.com / feeder taps tap conductors protection rule point overcurrent exception supplied required located where

240.21 Feeder Taps.

Photo Credit by: bing.com / feeder nec

NEC 2011 Feeder Tap Rules 240.21(B)(1) (13min:22sec) - YouTube

Photo Credit by: bing.com / taps tap conductors outside secondary feeder nec electrical rules 240 overcurrent phase converters rotary wanting learn canadian device they

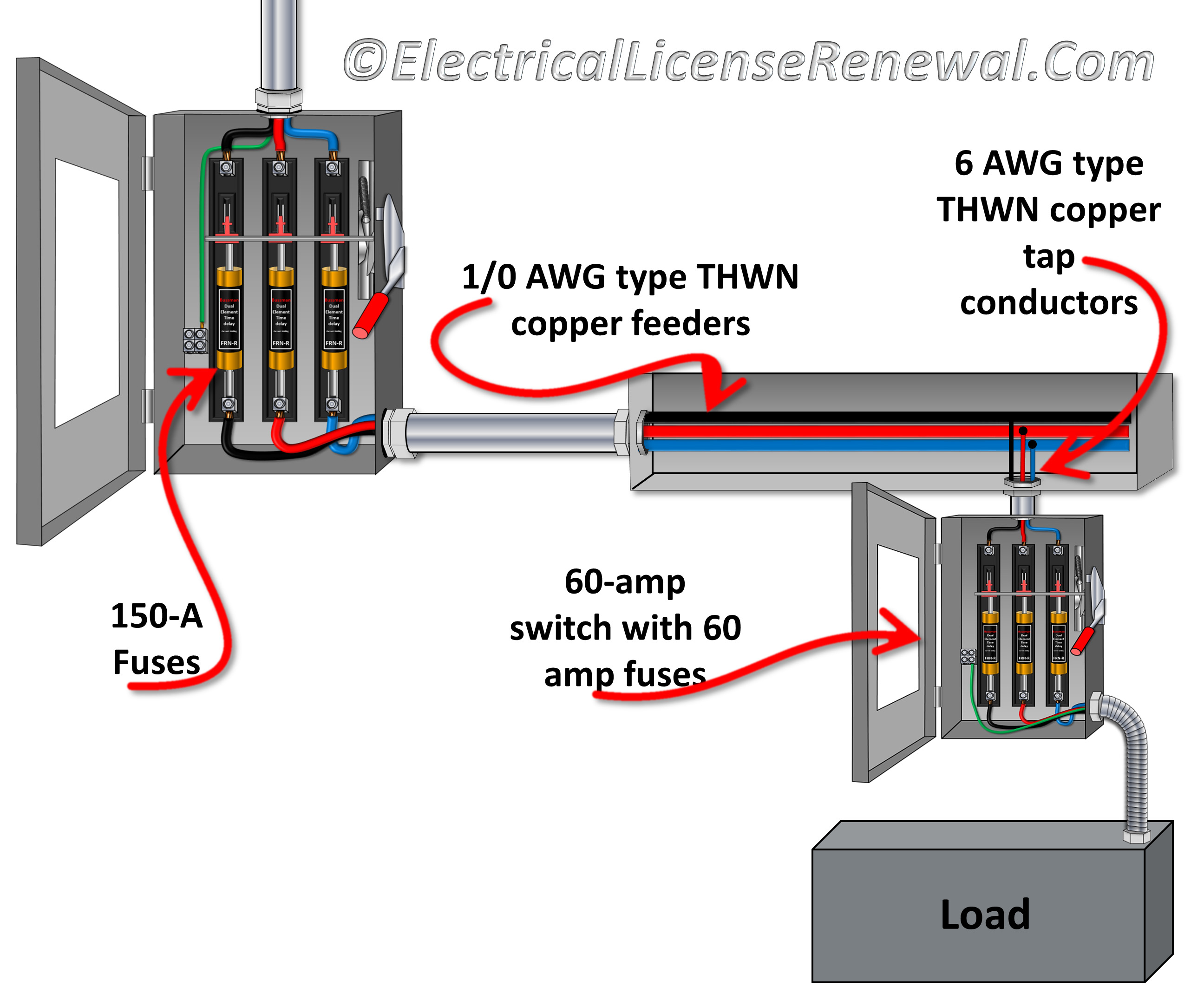

240.21(B)(1) Feeder Taps Not Over 3 M (10 Ft) Long.

Photo Credit by: bing.com / electrical tap feeder conductor nec conductors taps overcurrent ft over device equipment supplied

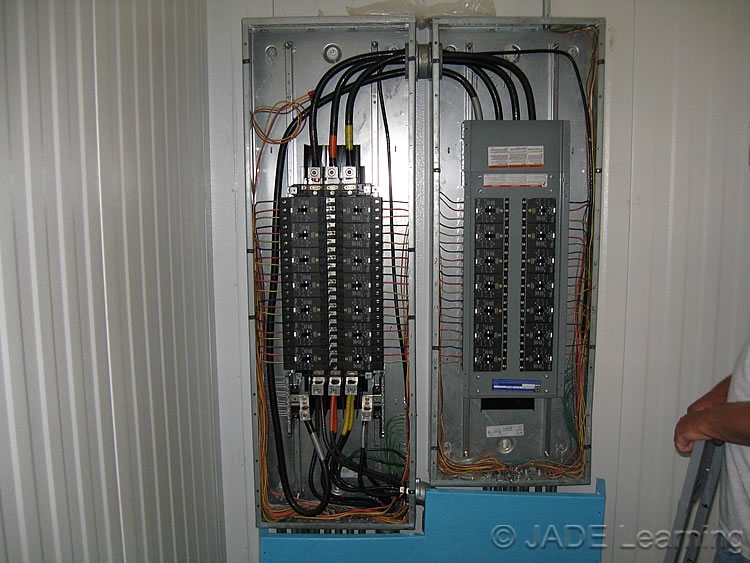

Feeder1_Taps_10FT – Jade Learning

Photo Credit by: bing.com / taps feeder1 10ft nec feeder tap rule foot

0 Response to "Feeder Tap"

Post a Comment